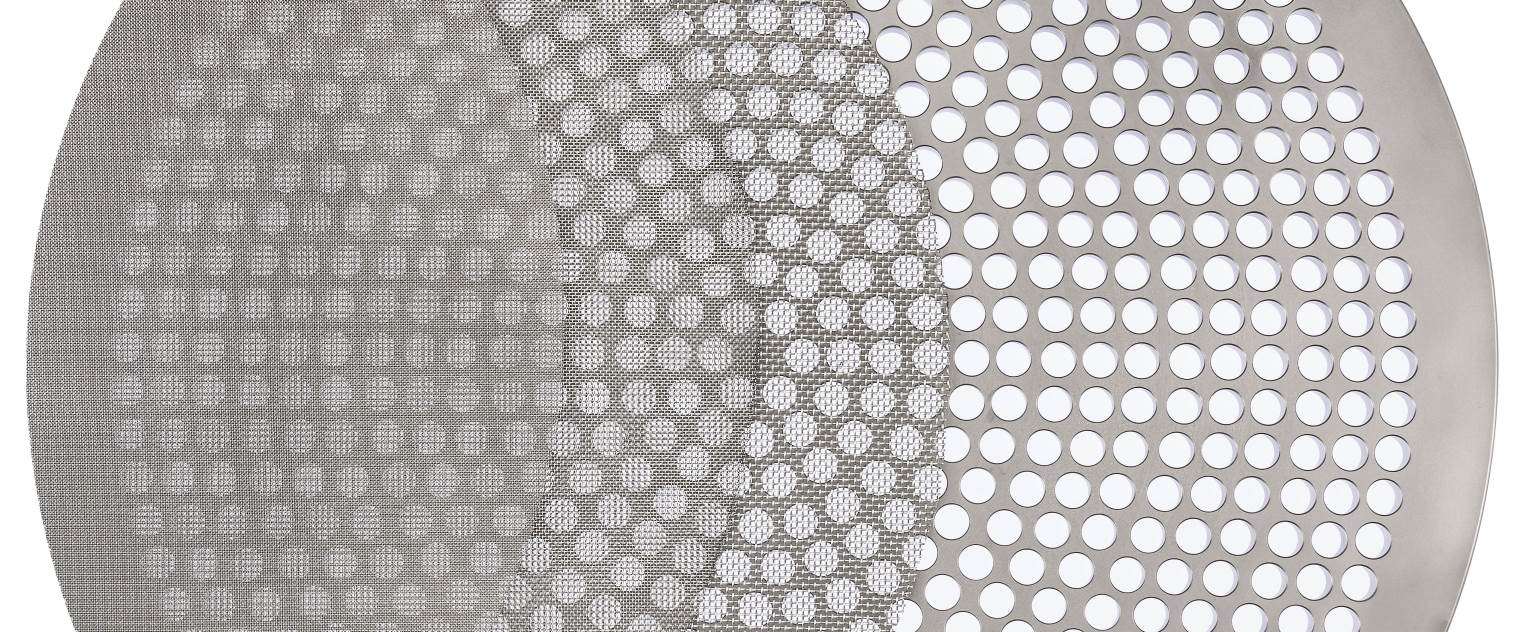

Fine Mesh Straining

Our core competence for the clean and gentle processing of rubber and silicone

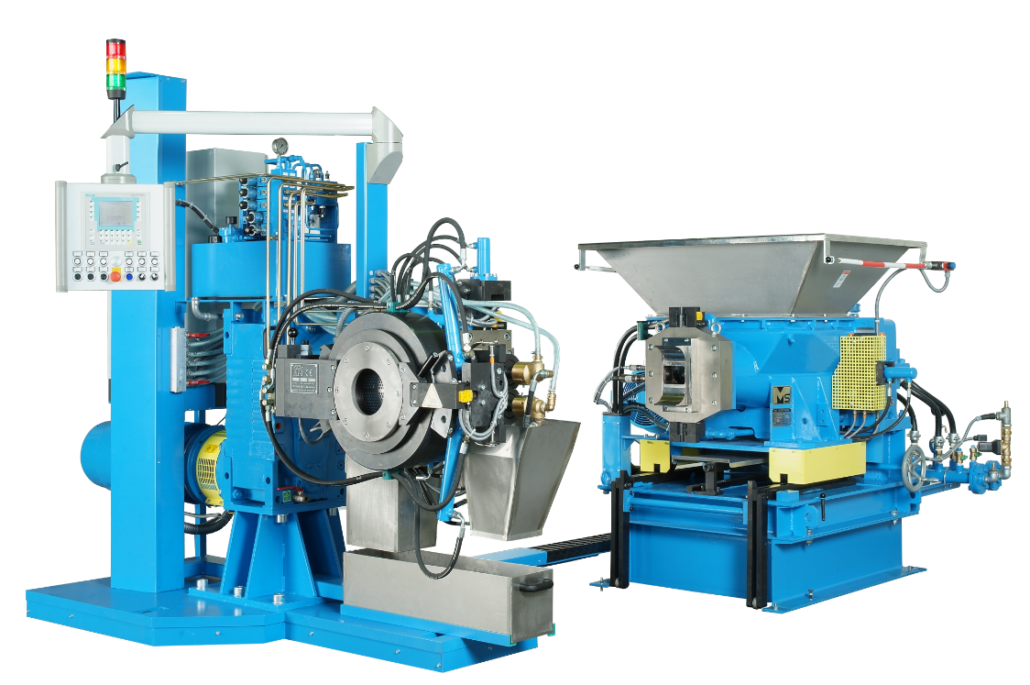

The roll-ex® gear pump extrusion system developed by UTH has become the global benchmark for fine mesh straining of rubber and silicone.

Fine mesh straining solutions are used for the fine filtration of rubber or silicone compounds. Impurities are retained in the screen and thus removed from the material. Depending on the quality of the mixture and the screen width, pressures of several hundred bar are required for this process. Through that the quality of the applied material can be improved significantly.

Straining rubber compounds is one of the main applications for gear pump extruders. Especially high quality products like those produced in the automotive industry, membrane technology, tire production etc. require very clean compounds.

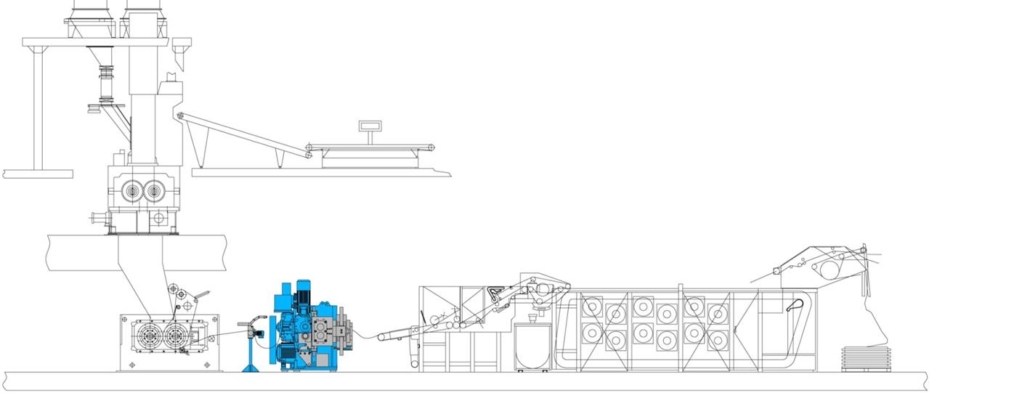

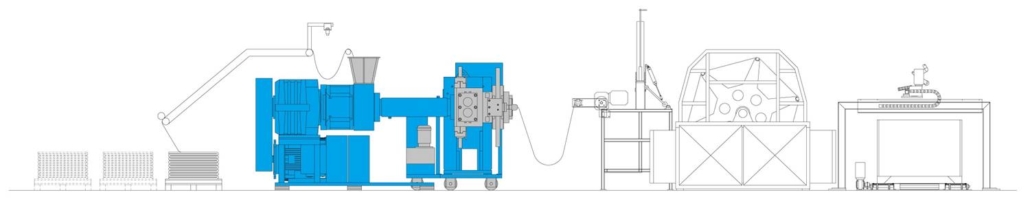

With throughputs of up to 10,000 kg/h, the gear extruder/strainer solutions are optimally designed for operation in larger mixing lines. The modular combination options of a gear pump and a two-roll feeding unit (TRF) or a conical twin-screw extruder (DSE) allow integration into almost any line concept.

Fine mesh strainers in mixing line

with the roll-ex® TRF model

with the roll-ex® DSE model

Fine mesh strainers offline

with the roll-ex® TRF model

with the roll-ex® SF model

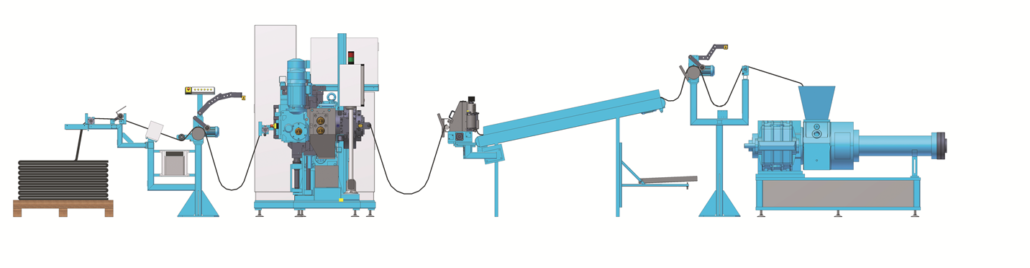

Fine mesh strainers in extrusion line

with the roll-ex ® TRF model

Fine mesh strainers of silicone compound

with the roll-ex® DSE model